Vibration Monitors are designed for military and commercial helicopters

Series 961/960-TX sensors monitor vibration generated by military and commercial helicopter engines, transmissions, and airframes.

» Read MoreCompact & Miniature Force Balance Accelerometers

Airborne applications SA-102BHC / SA-302BHC compact and SA-102MFTB / SA-302MFTA miniature precision accelerometers operate from +24 to +32 VDC aircraft power.

» Read MoreNew Sensor Designed to Measure Strain on Curved Mounting Surfaces

Accuracy, ruggedness, and ease of installation found in Columbia's flight-qualified Series DTD284, DT3747 models compensate materials commonly used in aircraft structural fabrication.

» Read MoreMeasurements In Low Frequency Micro-G Range

High sensitivity, ultra low noise use in seismic, low level, low frequency motion studies. SA-107LN is a single axis unit and SA-207LN, and SA-307LN are two and three axis units.

» Read MoreWhat's New

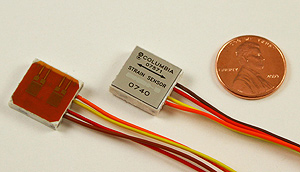

« BackNew Sensor Designed To Accurately Measure Strain On Curved Mounting Surfaces

Columbia Research Laboratories has introduced a new sensor designed to accurately measure strain on curved mounting surfaces. Series DT3747 sensors are customized to measure circumferential strain around the diameter of the surface to which it is mounted. Featuring the accuracy, ruggedness, and ease of installation found in Columbia's flight-qualified Series DTD284, DT3747 models are available to compensate materials commonly used in aircraft structural fabrication. Similar devices have been utilized to monitor rocket motor expansion. They can also be used in many industrial and military applications involving pipe expansion measurements, explosive body applications, aircraft surface load, and engine monitoring of all types.

Series DT3747 sensors are self-temperature compensating and offer a choice of cylindrical mounting radius. The specified mounting radius is custom molded into the body of the sensor providing a method of controlling operator alignment during sensor mounting. Columbia Model 5802 Strain Gage Amplifier is also available to power and signal condition the strain output of the sensor.

Accelerometers

Accelerometers Dynamic Pressure Sensors

Dynamic Pressure Sensors Fiber Optic Pressure Seals

Fiber Optic Pressure Seals Force Balance Inclinometers

Force Balance Inclinometers L.V.D.T. Products

L.V.D.T. Products Portable Vibration Meters

Portable Vibration Meters Signal Conditioning Instruments

Signal Conditioning Instruments Strain Sensors

Strain Sensors Vibration/Temp. Transmitters

Vibration/Temp. Transmitters